Smarter Concrete Inspections with Niricson’s AI & Drone Platform

One of the biggest problems for asset owners and government agencies all over the world is monitoring old civil infrastructure. Traditional inspections take a lot of time and effort, and they often miss defects that are hidden and are below the surface in concrete structures like bridges, spillways, and dams.

Niricson and AUAV are now making detection more efficient with DRONIC®, a drone-based inspection platform with multiple sensors, and AUTOSPEX, an AI-powered system for identifying and notifying defects. Together, they make concrete condition evaluations more quickly, securely, and accurately, with deeper insights than ever before.

The Technology Behind Niricson

Founded in 2020, Niricson is based in Victoria, Canada. The company is a leader in using drones to monitor the health of structures. Their patented systems allow for full evaluations of high-value assets using:

DRONIC®: Drone-Based Multi-Sensor System

A fully integrated drone payload system combining:

- High-resolution optical imaging for visual detection of cracks.

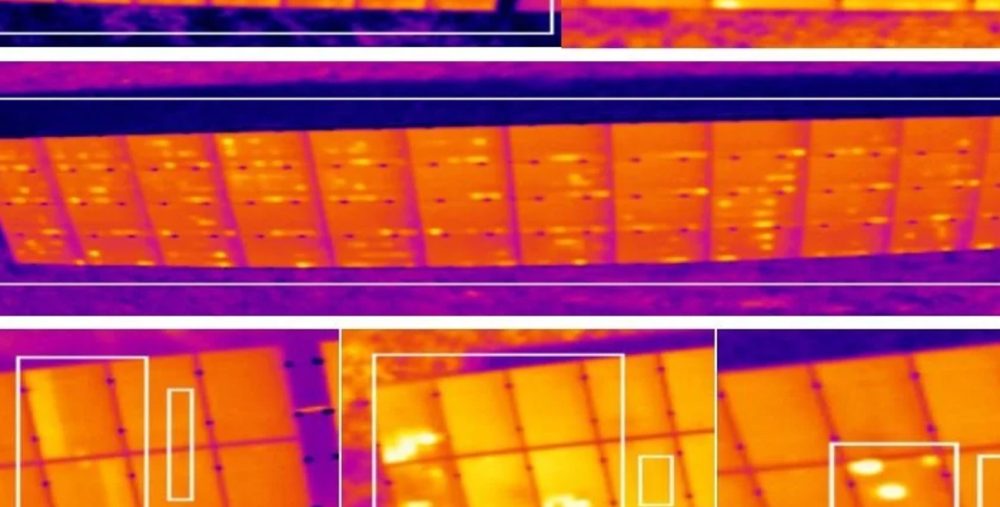

- Thermal sensors identify changes in temperature and moisture ingress.

- Acoustic sensors that can detect subsurface delamination up to 200 mm deep.

All data is collected contactlessly and is linked to a specific location, even on vertical or hard-to-reach concrete surfaces.

AUTOSPEX: AI-Powered Condition Assessment Platform

- Locates and sorts cracks, spalls, delamination, and surface wear on its own. Keeps record of alterations over time to check for long-term damage.

- Creates reports and visualisations that asset managers and engineers can utilise promptly.

- Supports integration with asset management platforms and digital twins.

Key Applications of Niricson Technology

AUAV’s authorised pilots and testing engineers operate the Niricson system in important areas like Australia, the UK, and the US. This means that clients can now get digitally accurate, repeatable inspections of:

Dam Walls & Spillways

- Identify cracks, seepage paths, and delamination.

- Create 3D models and acoustic maps for early failure warnings.

- Cut down on the requirement for inspections that use ropes, scaffolding, or divers.

Bridges & Elevated Structures

- Check the piers, beams, and undersides for cracks through visual and acoustic inspection.

- Measure how much the surface has worn down and track movement over time.

- Use drones to easily reach narrow or dangerous areas.

Airfields & Concrete Slabs

- Find cracks and wear on runways or slabs by looking at thermal and optical data.

- Automate visual inspection of joint degradation and settlement indicators.

Retaining Walls & Civil Assets

- Detect shallow and subsurface voids using acoustic data

- Monitor concrete movement in retaining structures, tunnels, culverts

Why Choose AUAV + Niricson for Concrete Inspection?

|

Feature |

Niricson + AUAV |

Traditional Inspections |

|

AI crack classification |

✅ |

❌ (Manual) |

|

Subsurface acoustic testing |

✅ |

❌ |

|

Change tracking over time |

✅ |

❌ |

|

Safety risk |

Low (drone-based) |

High (scaffolds, rope access) |

|

Report turnaround |

Fast (AI-driven) |

Slow (manual review) |

Industry Credentials & Integration

AUAV operates in line with international safety, inspection, and quality standards, backed by:

- CASA-certified drone operators and structural engineers.

- ISO-aligned processes.

- Experience across dam safety, transport infrastructure, and utilities.

- Integration-ready outputs for digital twin platforms, CAD, and GIS.

Book a Drone Concrete Inspection or Sample Report

AUAV is a recognised drone company in Australia, honoured to offer advanced drone-based concrete inspections using Niricson’s platform. This solution can greatly improve how your company plans maintenance, assesses risk, and extends the life of civil concrete assets like bridges, dams, airfields, and other structures.

FAQs

What is DRONIC, and how does it work?

DRONIC is a system for collecting data from drones that uses optical, thermal, and acoustic sensors to check the condition of concrete structures on the surface and beneath them. It allows you to collect high-resolution data contactlessly.

What defects can AUTOSPEX detect?

Using visual and sensor data, Niricson’s AI platform AUTOSPEX can identify cracks, spalling, surface erosion, delamination, and changes in structure over time.

Can this replace manual concrete inspections?

Yes, in a lot of cases. It lowers down on the need for scaffolding, rope access, or large inspection teams, as well as gives you more reliable data with change-tracking capabilities.

How deep can it detect delamination or voids?

The acoustic sensor can find delamination up to 200 mm deep, but this depends on the material and structure.

Is this system suitable for active or in-service assets?

Yes. The system can inspect a lot of structures without interrupting work, which is ideal when access is limited or time is short.

What are the benefits of AI crack detection?

AI eliminates human bias, speeds up data analysis, and lets you track conditions consistently and repeatedly over time, which is very important for long-term managing of assets.