Offshore inspections consume a lot of time and money and put crews into significant risk. Rope access, scaffolding, vessel hire, and shutdowns all add pressure to already complex sites.

Abyss Solutions offers an alternative: self-driving inspection tools that use AI corrosion mapping and machine vision to deliver consistent results on big, hard-to-reach structures.

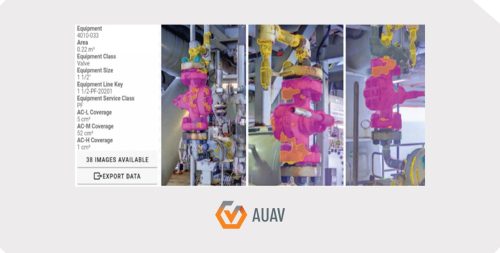

AUAV and Abyss Solutions work together to use drones and lasers to scan offshore assets. Together, this gives operators a reliable way to check the condition, plan maintenance, and cut down on the need for manual inspection teams.

Abyss Solutions Technology

Abyss Solutions was founded in 2014 and brings together experts in robotics, optics, and computer vision to provide accurate, high-volume inspection data for ports, jetties, oil and gas, and marine structures. Their workflow is built around three steps: acquire, analyse, and act.

1. Acquire: Autonomous and Drone-Based Data Capture

Abyss Solutions and AUAV use a mix of aerial, surface and subsea platforms to collect:

- High-resolution photos to assess corrosion and coatings.

- Geometry and deformation checks using laser scanning data.

- Comprehensive visual documentation appropriate for digital twin workflows.

This approach covers a large portion of an asset while cutting down on time spent on ropes, scaffolds, or structures over water.

2. Analyse: AI Corrosion Mapping and Machine Vision

Abyss Solutions’ machine learning tools process large datasets and classify:

- Corrosion levels.

- Coating breakdown.

- Surface wear.

- Structural deformation.

AI produces a consistent record across inspections and lessens subjectivity. Long-term integrity planning is supported by the results that asset owners can compare year after year.

3. Act: Digital Twin and Maintenance Planning Through Abyss Fabric

Inspection data feeds into Abyss Fabric, a digital environment that supports:

- Digital twin visualisations.

- Maintenance priority lists.

- Integration with common Inspection Management Systems (IMS).

- Long-term trend reporting.

This lets engineers make decisions based on data instead of just relying on manual visual checks.

Key Applications in Offshore and Marine Environments

Abyss Solutions and AUAV support a wide range of assets in the marine and energy sectors.

1. Offshore Oil and Gas Platforms

- AI corrosion mapping on topsides.

- Using lasers to scan structures for modelling.

- Keeping track of the condition of walkways, risers, decks, and support frames.

2. Ports, Wharves and Jetties

- Wide coverage without having to stop operations.

- Geometric and visual records for long-term planning.

- Corrosion zones and early structural issues are identified.

3. Subsea and Water Infrastructure

- Evaluations of underwater assets like pipelines and aqueducts.

4. Multi-Environment Integrity Programs

- Combined support for subsea, surface, and drone inspections.

- Unified reporting for large and intricate facilities.

Why Operators Choose Abyss Solutions and AUAV

1. High Coverage

Up to 95% of an asset’s surface can be captured by autonomous and drone-based tools. This way engineers get a clear picture of its condition.

2. Lower Risk

Reduced exposure to heights, over-water work, and vessel mobilisation results from fewer employees being stationed in dangerous areas.

3. Less Disruption

The majority of inspections can take place while the asset is still in use.

4. Lower Carbon Footprint

Less reliance on large access crews, ships, and helicopters.

5. Consistent Reporting

Repeatable measurements are provided by AI throughout each inspection cycle.

6. Better Use of Maintenance Budgets

Engineers can focus their work where it is needed most if they have insight into how severe and widespread corrosion is.

Abyss + AUAV vs Traditional Offshore Inspection

|

Feature |

Abyss Solutions + AUAV |

Traditional Methods |

|

Corrosion detection |

AI-driven |

Manual |

|

Coverage |

High |

Limited by access |

|

Safety |

Low risk |

High exposure |

|

Carbon impact |

Reduced |

Higher |

|

Reporting time |

Fast |

Slow |

|

Integration |

Digital twin + IMS |

Mixed or manual |

Industry Considerations and How the Partnership Supports Operators

1. Technology Adoption

Some organisations are moving from established inspection routines. AUAV and Abyss can present combined outputs to support internal approval processes.

2. Integration with Existing Systems

Abyss Fabric connects with common asset and inspection management platforms, reducing workflow disruption.

3. Asset Variability

Operators and environments have very different offshore structures. AUAV modifies capture plans to fit conditions, weather windows, and safety requirements, while Abyss creates unique workflows for each asset.

AUAV Capability for Offshore Capture

AUAV strengthens the offering by providing:

- CASA/FAA and CAA-certified offshore drone pilots.

- ISO-aligned operating procedures.

- Laser scanning programmes for experts.

- Detailed modelling appropriate for engineering evaluation.

- Delivery across Australia, the UK, Europe, and the US.

For oil and gas and marine assets, this provides clients with a comprehensive data-capture and analytics pathway.

Book Drone or Laser Capture for Offshore Facilities

AUAV supports Abyss Solutions with precise, consolidated offshore inspection workflows, laser scanning and drone capture. For offshore projects in Australia, the UK, Europe, or the US, connect at contact@auav.com.au

FAQs

What does Abyss Solutions specialise in?

Abyss specialises in AI corrosion mapping, machine vision, and autonomous inspection for offshore and marine assets.

How does AI improve corrosion assessment?

It eliminates subjectivity and yields uniform outcomes throughout full-surface coverage.

Can this reduce the need for rope access?

Indeed. Crews don’t need to work over water or at heights to inspect numerous locations.

What is Abyss Fabric?

It is a digital twin and reporting platform that is used for reviewing conditions, scheduling maintenance, and integrating data into asset-management systems.

Can inspections occur during normal operations?

Yes. The majority of capture workflows do not require shutdown.